Computer-Aided Design

Assignment

- Model (raster, vector, 2D, 3D, render, animate, simulate, ...) a possible final project, and post it on your class page

Files

Hand drawn cloud for lasercutting (cut and engrave .svg-file)

Vector & Inkscape

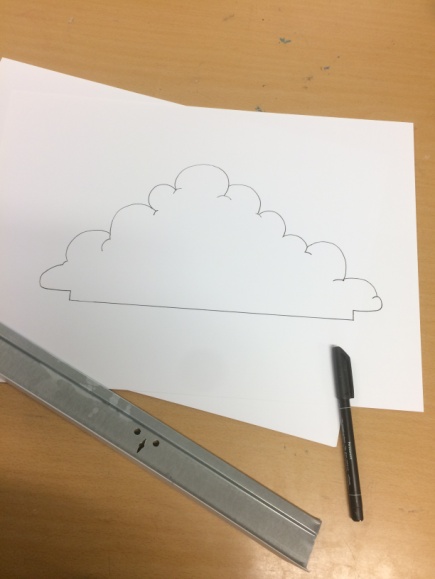

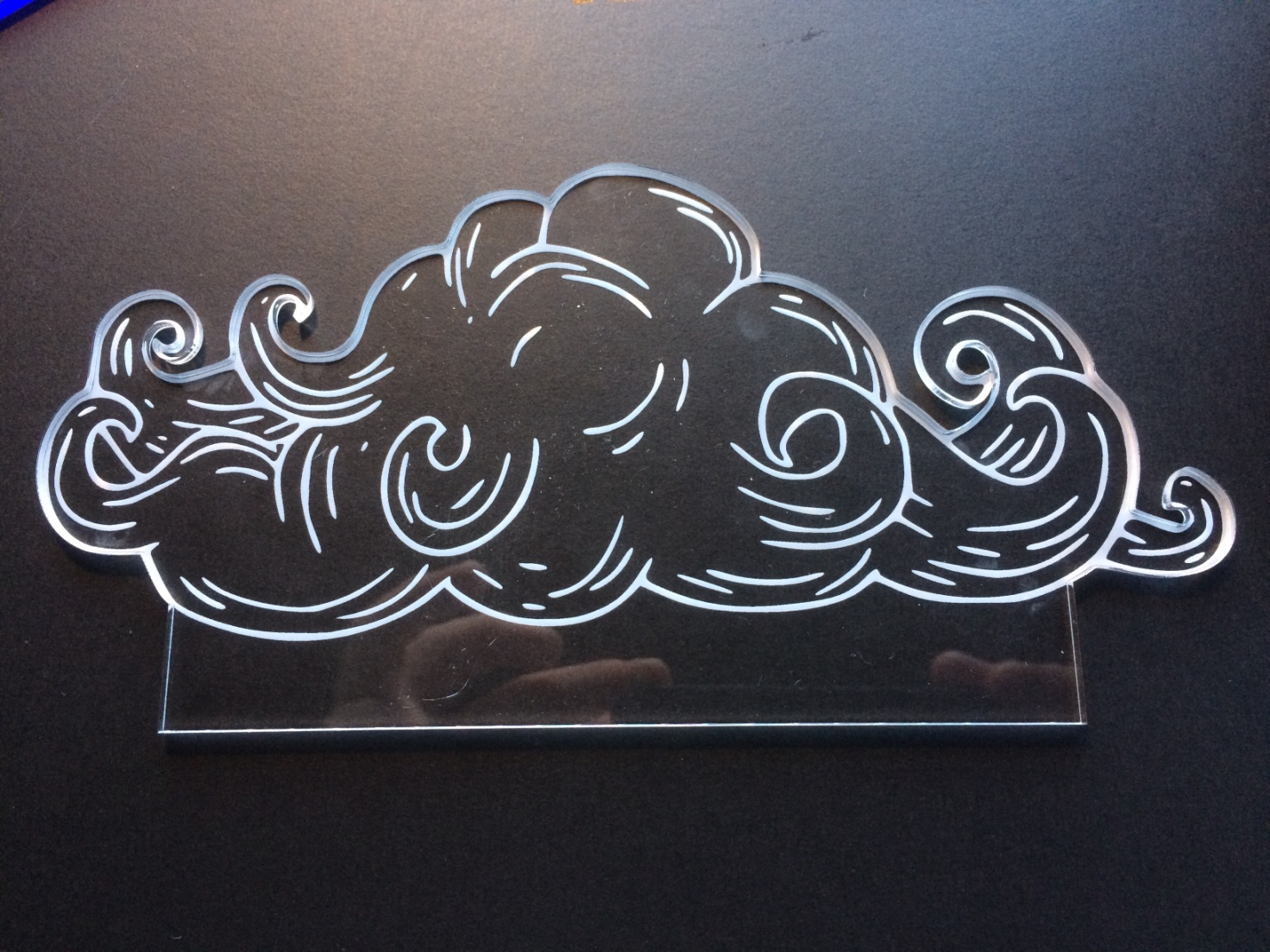

My ideas for the design of the lamp was to draw different clouds and vectorize them to be able to cut them in different colored flourished plexiglas. I have drawn different clouds by hand and want to cut and engrave the clouds on the laser. At first I cut a simple cloud in blue but when I lit it up there was not much light. So I had to draw another one with some curves inside for engraving. This way the led-light will glow in the engravings creating more light in the lamp.

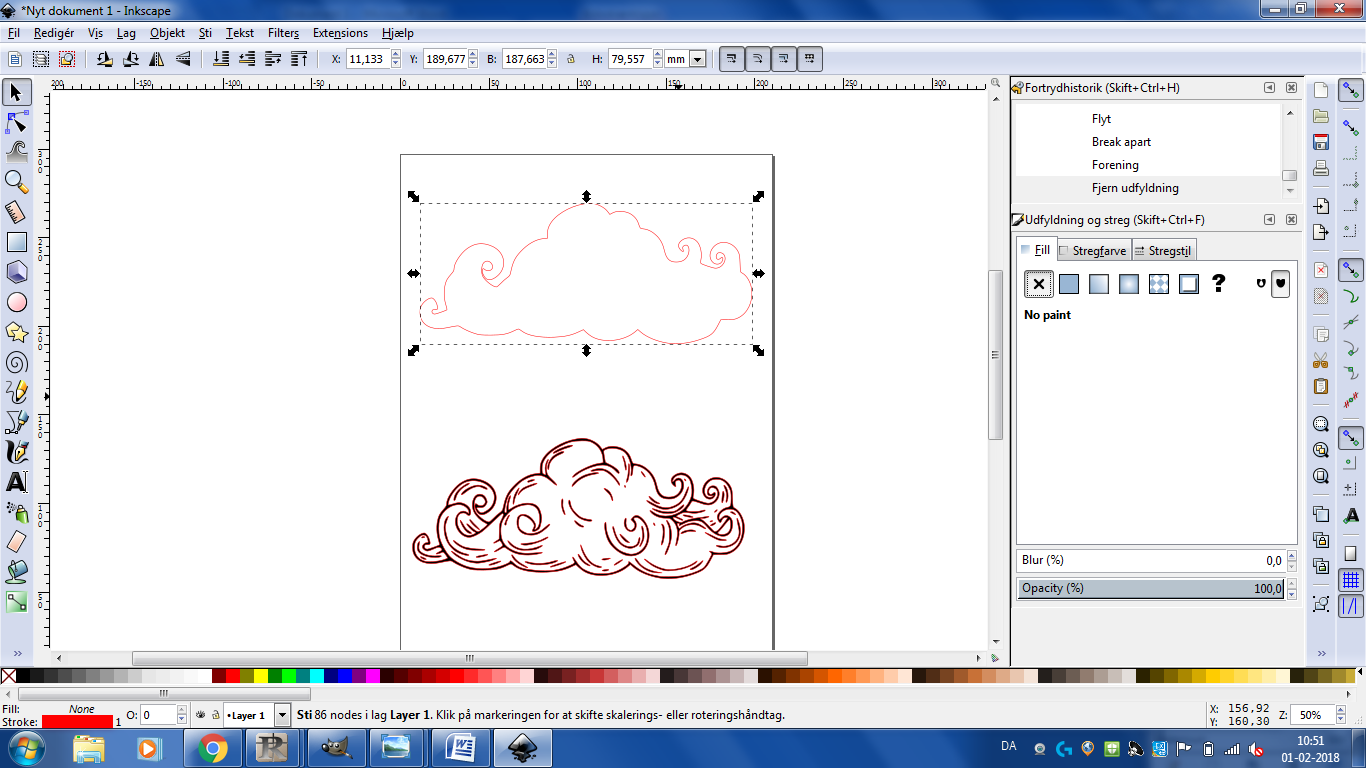

In Inkscape I had to vectorize my drawing and devide my drawing into different colors with different settings. So my image outline of the cloud has to be cut through the Plexiglas and the curves inside the cloud has to be engraved. So at first I made two copies of my cloud and made the image outline of my drawing with the first copy. We have an Universal laser at the lab, so I needed the outline to be the color red and the thikness of the line needed to be 0.025.

Then I startet up with the other copy of the cloud that was going to be the engraved curves in the cloud. I needed a thick line so the engraving would be more visible and the settings for the Universal had to be the color black.

At last I grouped the two images and aligned them to fit perfectly and cut a sample in transparent Plexiglas on the laser. I tried to put light through the sample and the engraving lit up a whole lot more. I’m very satisfied with the cut.

Vinylcutting with Roland SV-15 and Cut Studio

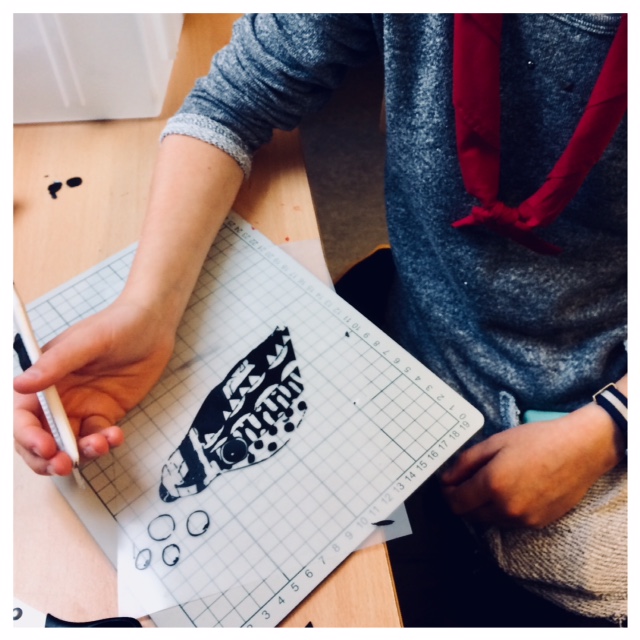

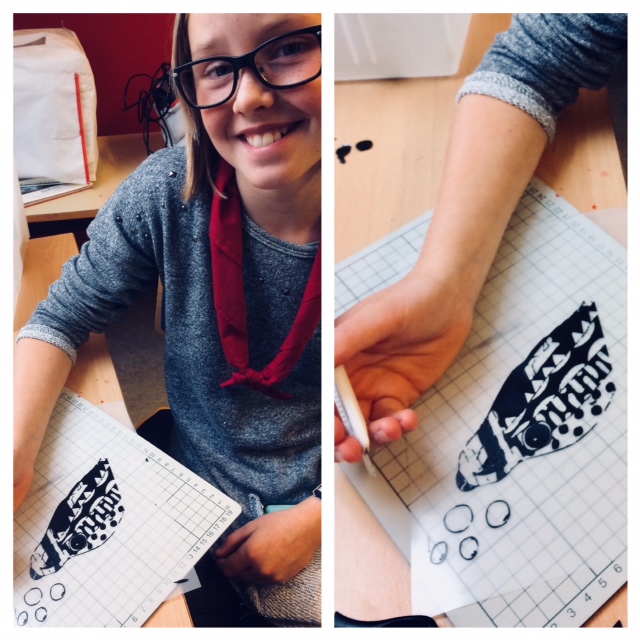

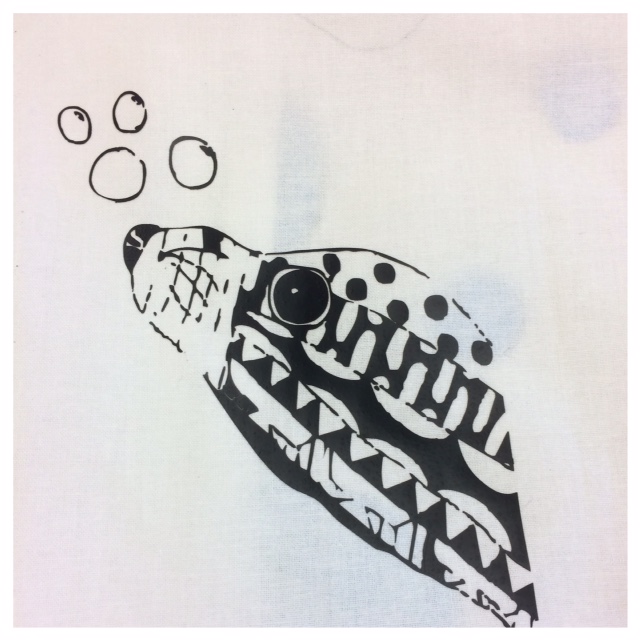

To work with 2D design and the vinyl cutter. I wanted to try out how this could fit in as an assignment for a student in a public school. So I worked with a girl named Ninna (age 11). We used a Roland SV-15 with the Cut Studio software.

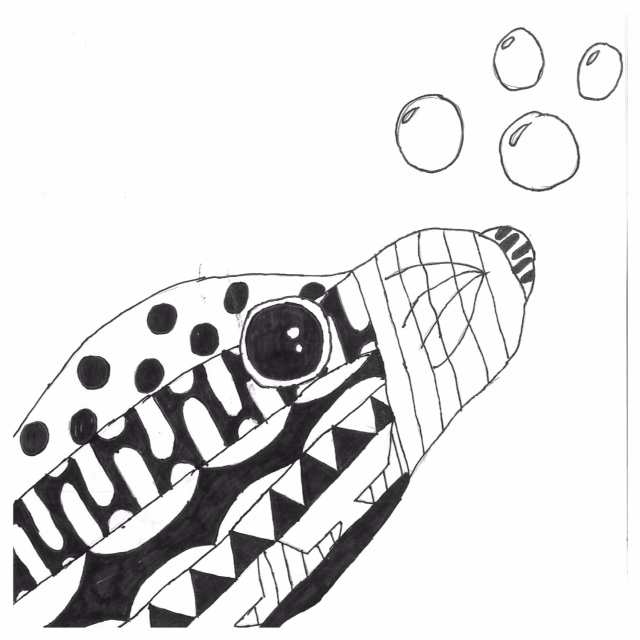

I liked the idea of a drawing by hand going to be digitalized, so the process of going from analog to digital. Scan it as a jpg and vectorize it in Cut Studio. At last we wanted to make the cut in textile vinyl and put it on a hand stitched pillowcase.

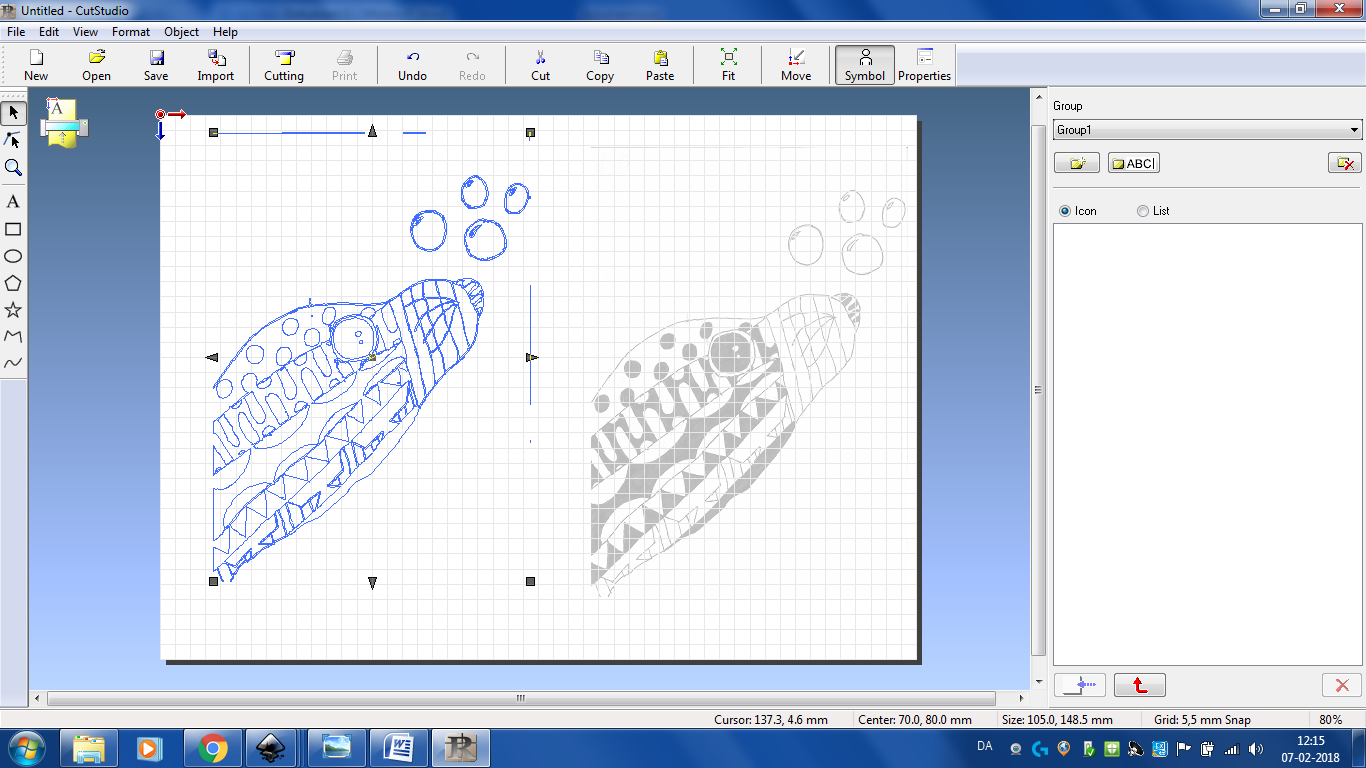

Ninna made the drawing with a pencil and then a thin marker. We scannet the drawing and imported it to Cut Studio.

Cut Studio is the software the belongs to the Roland vinylcutter. The software is quite easy to use but it is also missing some tools compaired to Inkscape.

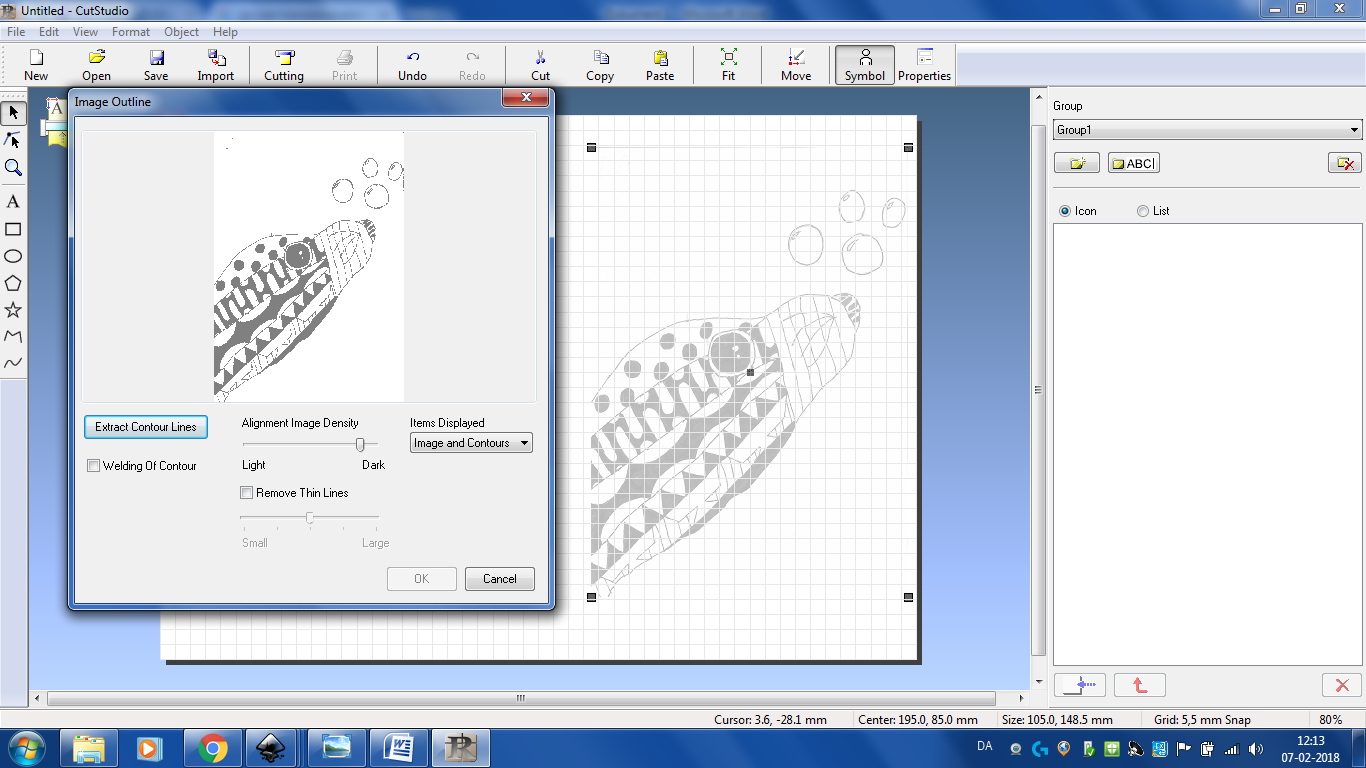

When that is said it actually had a very tool tool called Image Outline that let you extract contour lines and adjust the alignment image density. I think this tool gives a lot of opportunities to work with handmade drawings with the vinylcutter.

One big problem that we learned was that Cut Studio don't let you export files that are usebel with other brands. It is for an example not a possibility to generate a PDF or SVG file. In the last picture you see the pillowcase with Ninnas seal on it. I really love that you can see that it is analog drawn but still a file that you can develop on or print again for several pieces.

Press Fitt Construction

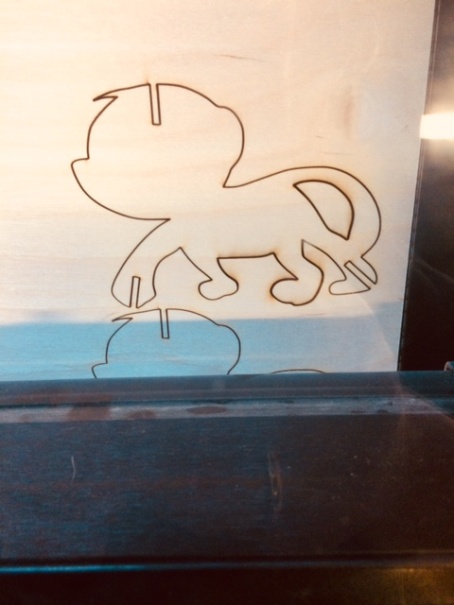

Peter Dahl vs. Curious George

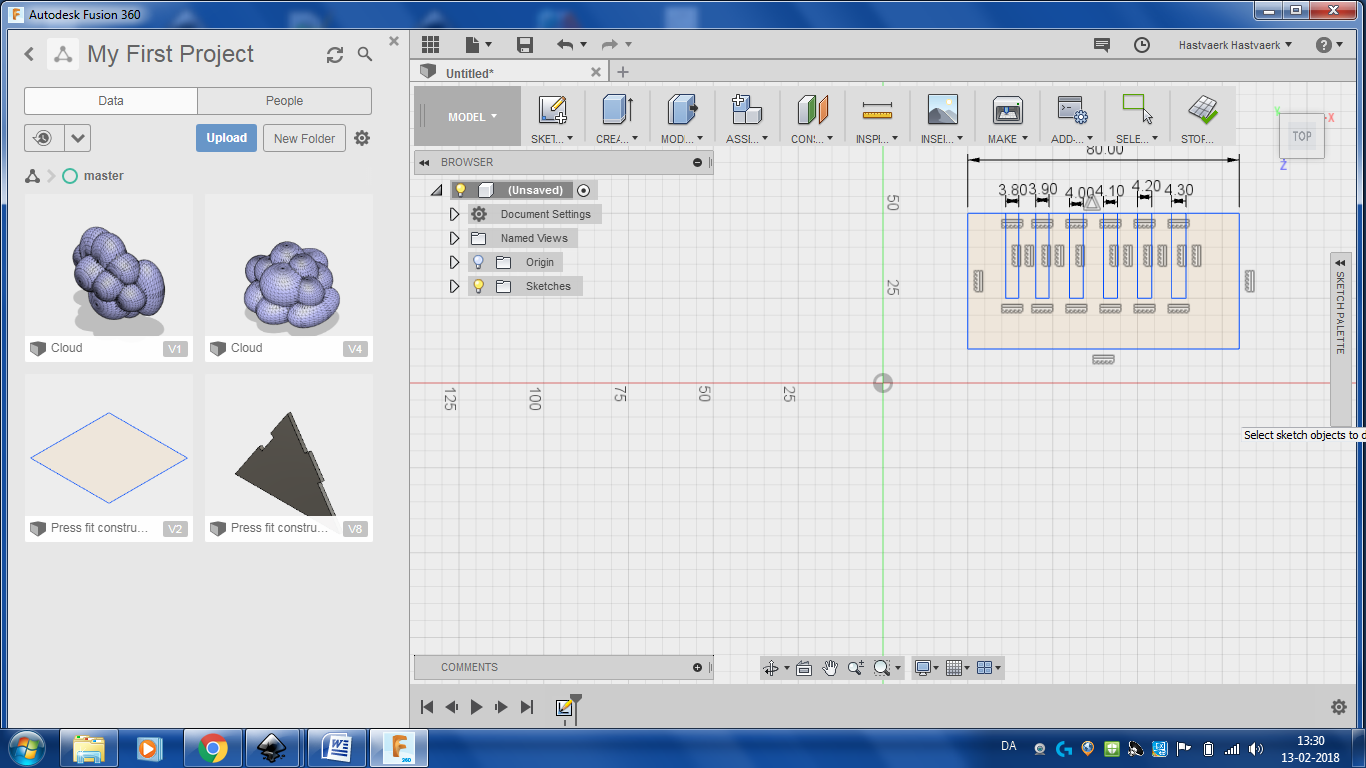

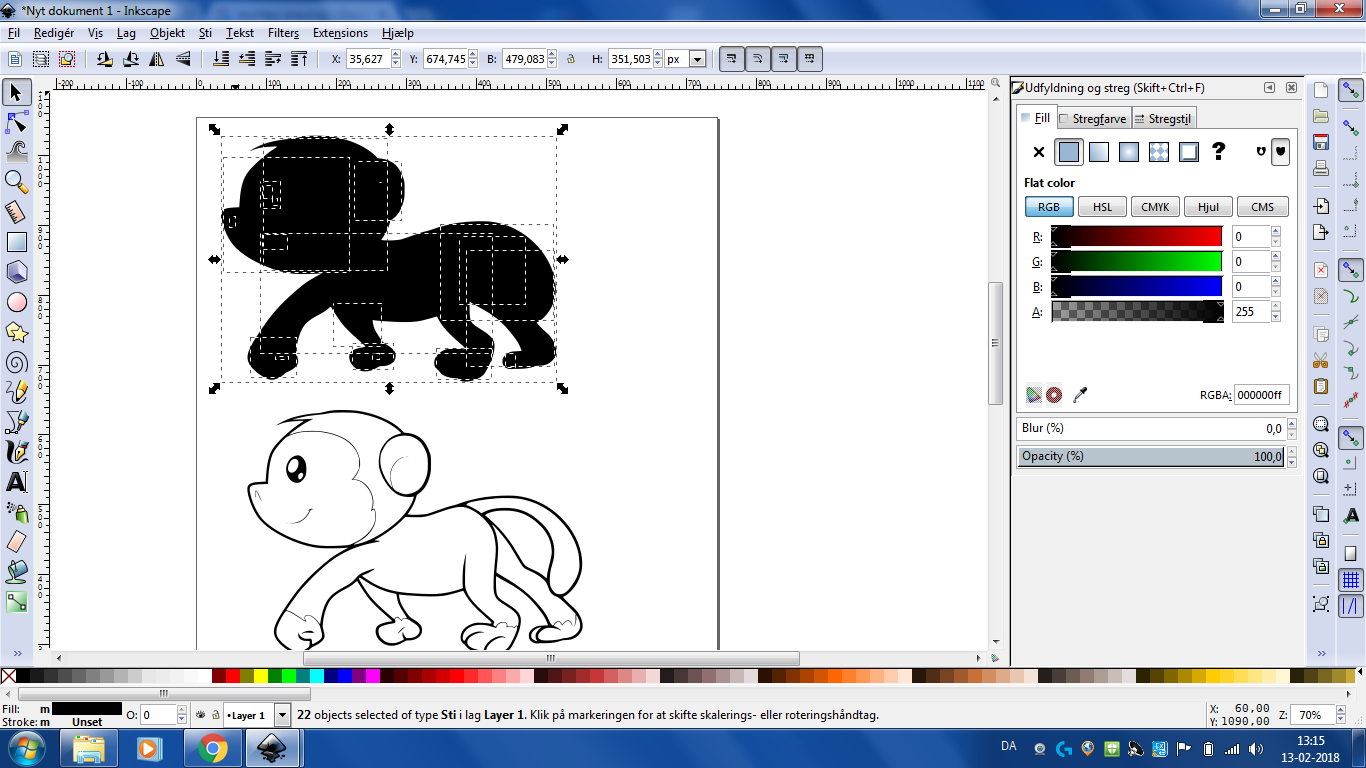

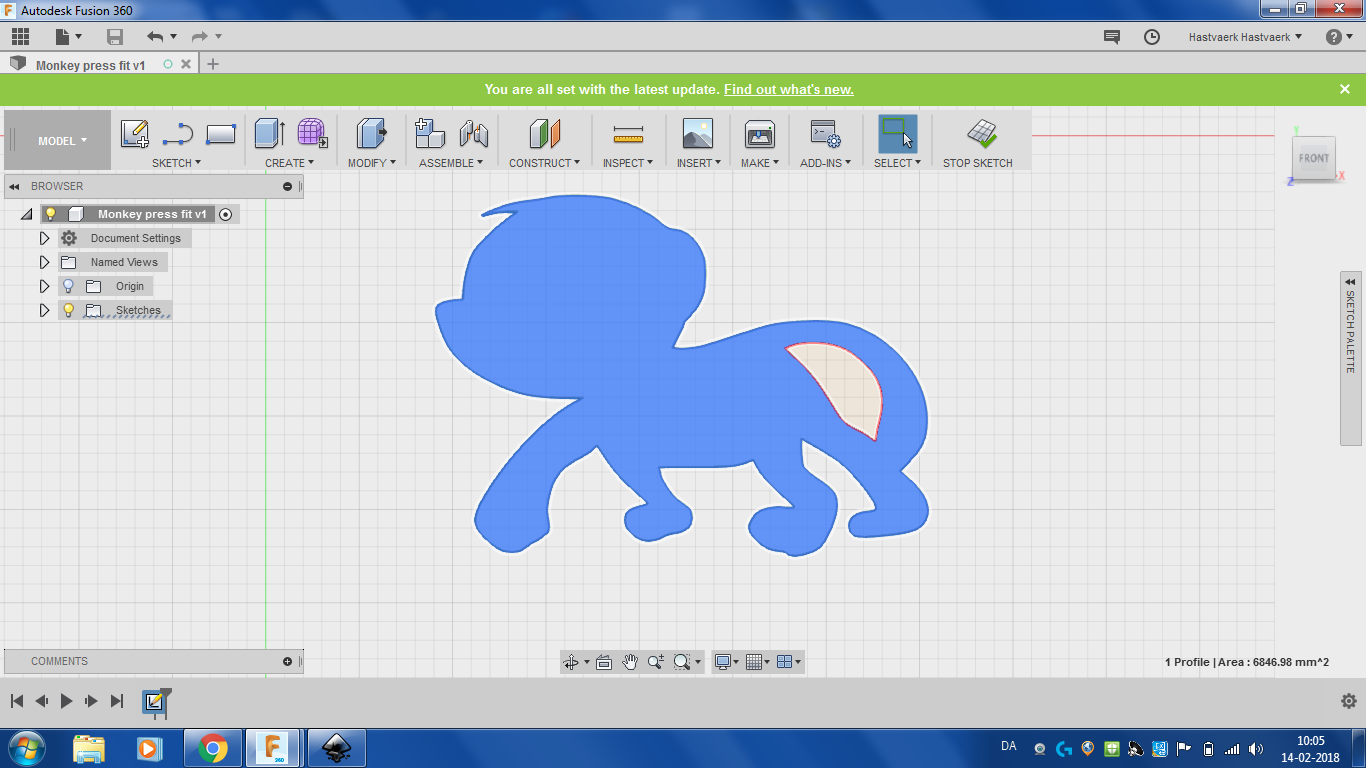

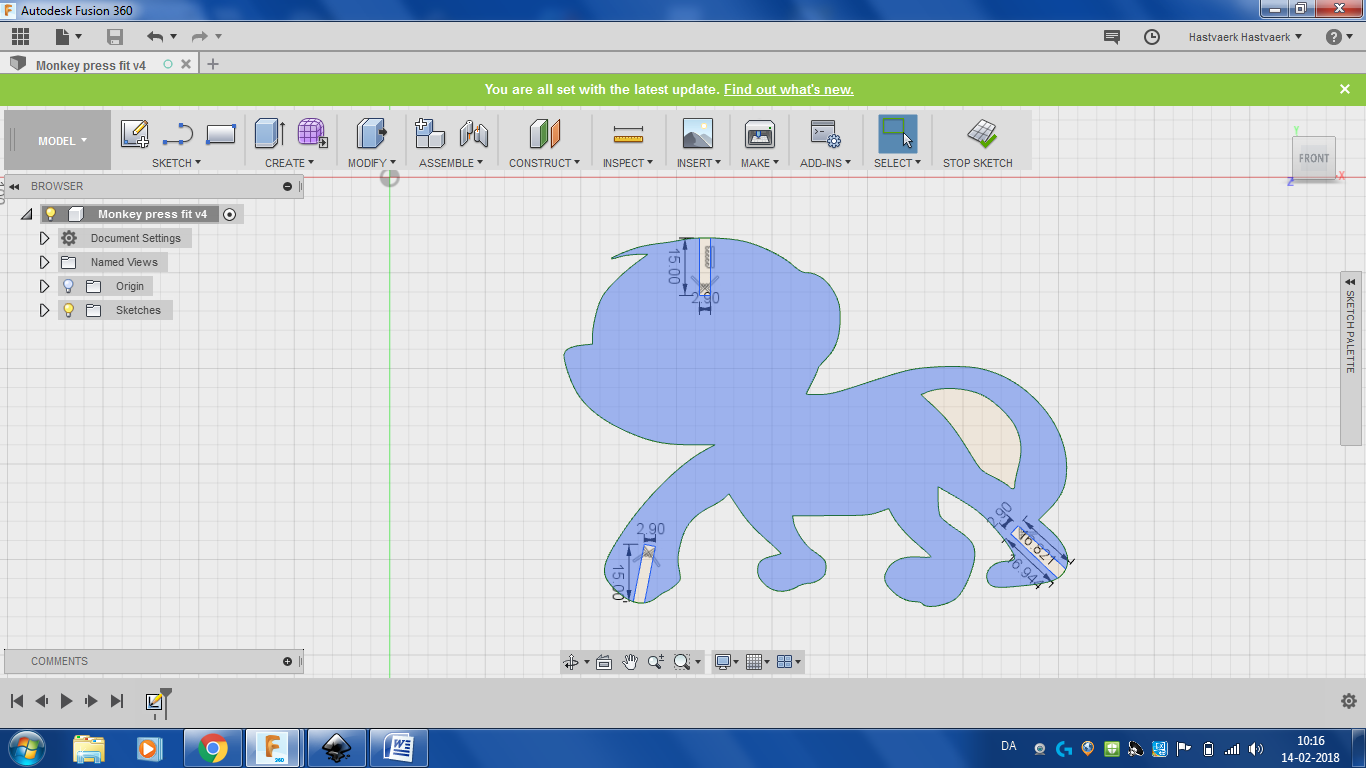

My name is very similar to the Danish name of Curious George. So I wanted to make a press fit construction toy for my daughters to play with. My plan is to make these small plywood monkeys that could fit together in varies ways and the combine it with a big tree and maybe a small hat.

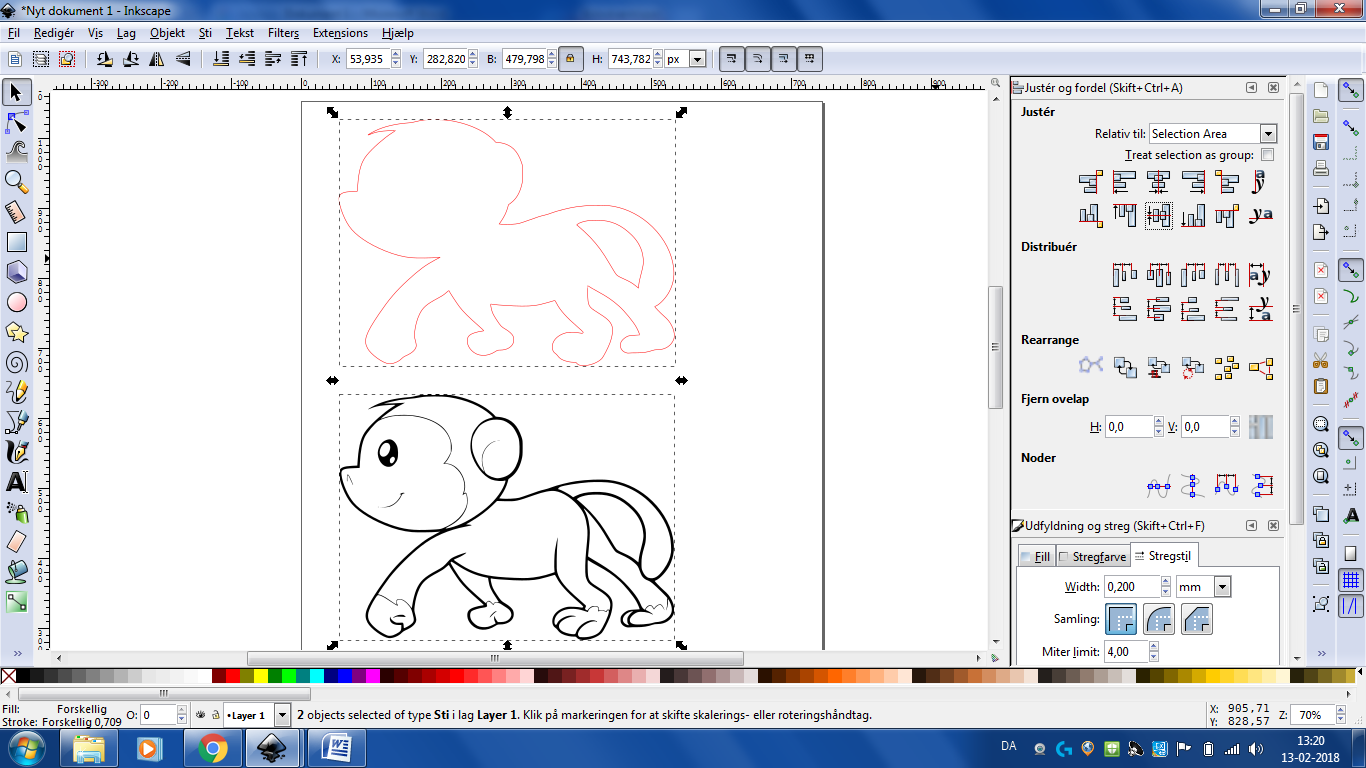

I started out with a drawing of a monkey that I found on Google but I needed to focus on the outline of the picture and then maybe later on engraving the black lines. I used the software Inkscape for this. At first I needed Inkscape to trace my picture so I could work with the vectors. By using Path and then break up the picture was now divided into pieces. Then I deleted the inner pieces so I only had the outline of my drawing and sawed it as a svg-file. This file I inserted into Fusion 360 because I like to make the slots and measurement in Fusion 360 (and also to rehearse my use of Fusion 360 and the mix of software use).

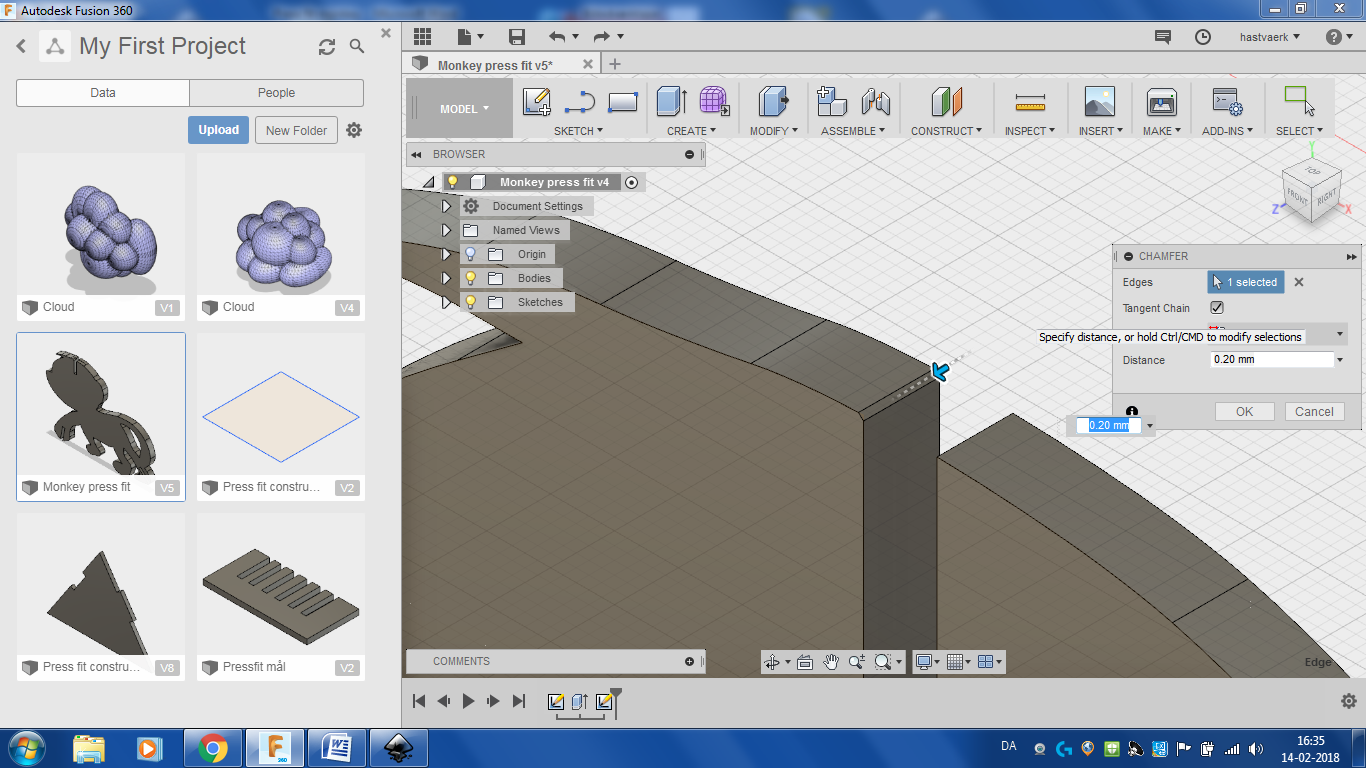

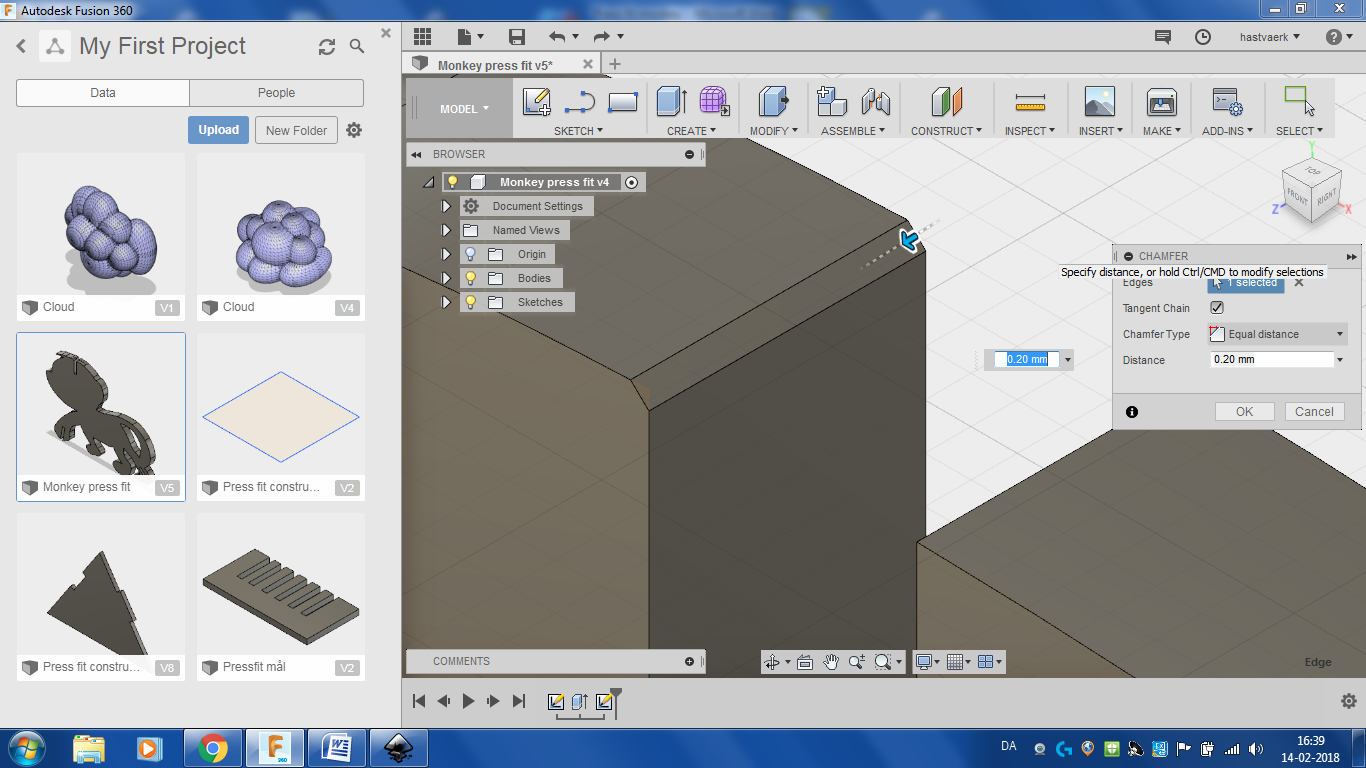

Chamfer

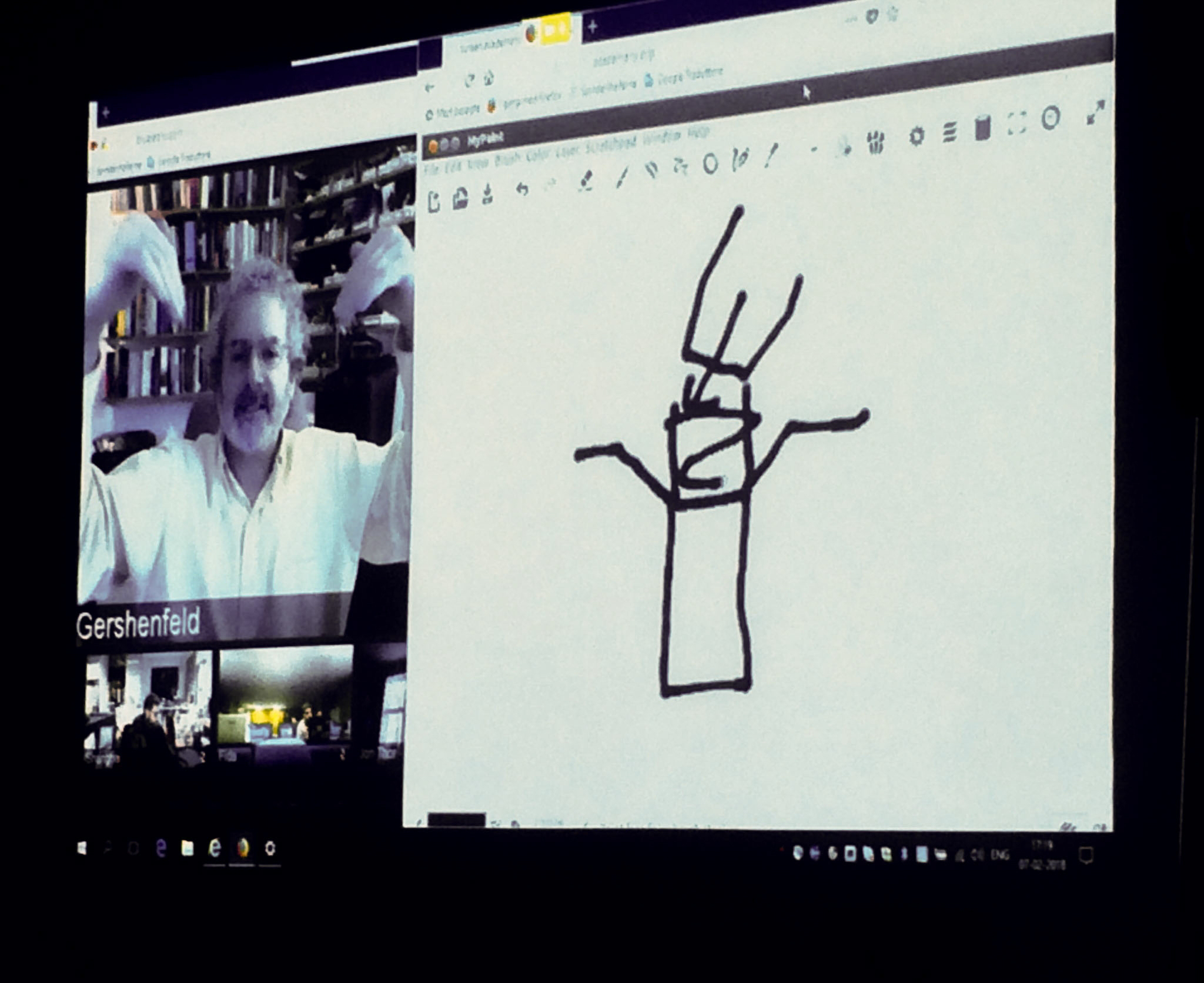

Neil Gerschenfed talked about the importance of Chamfers. I used the chamfertool in Fusion 360 to make small chamfers to my monkey's slots (distance 0,20mm). It really made the press fit snap easy, but really snap because of the compression of the material.

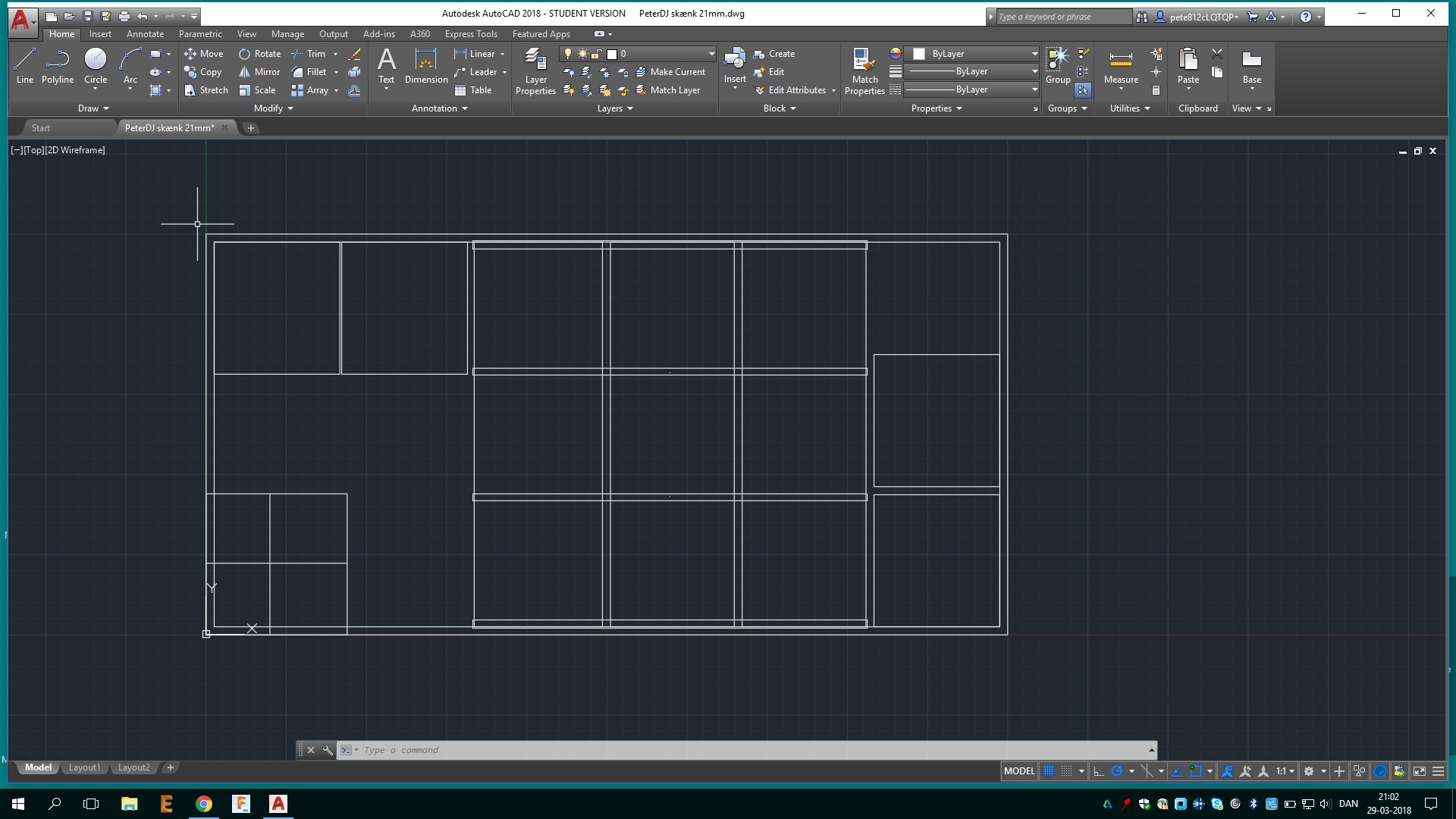

"Making something big" and 2D drawing

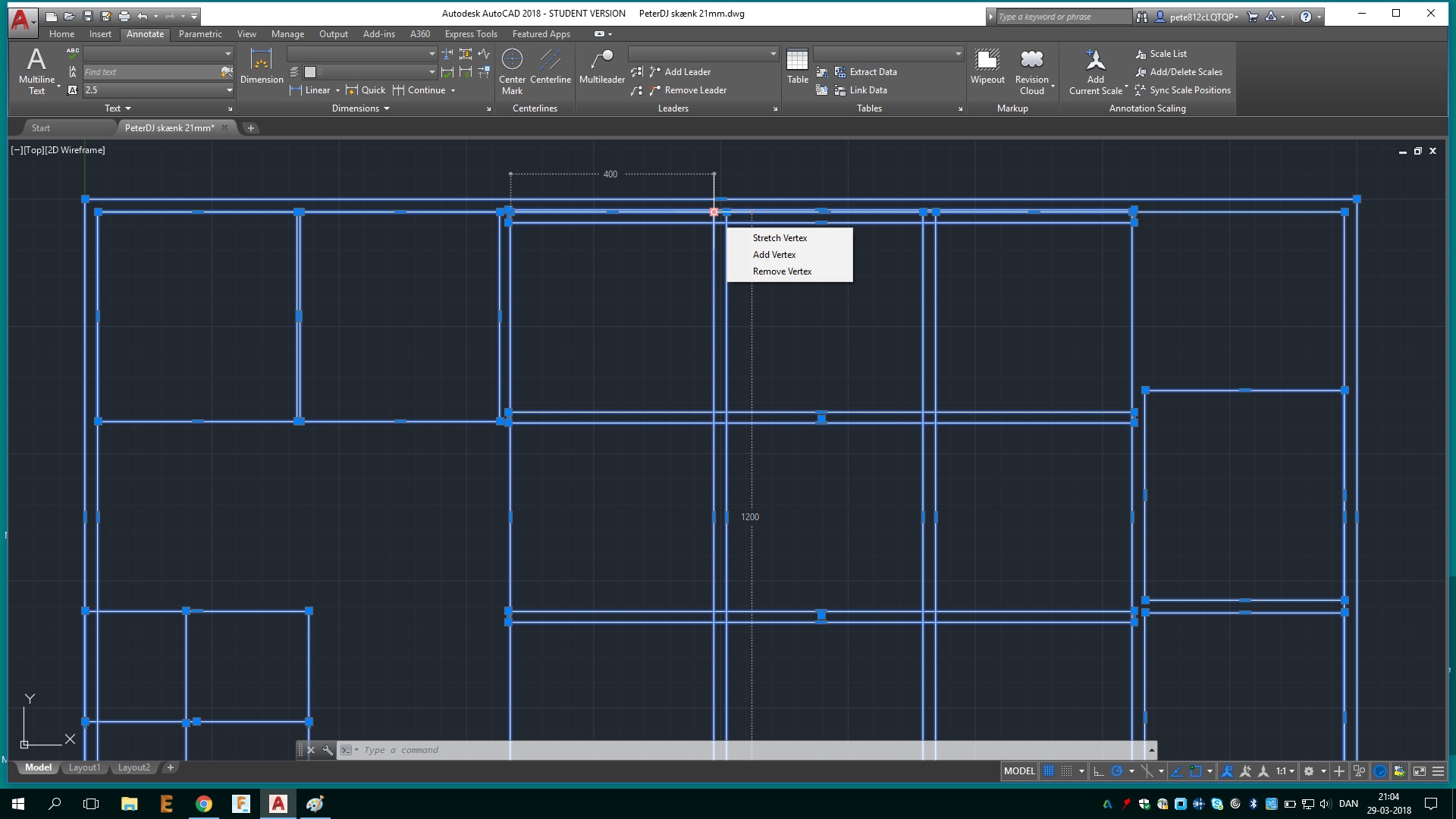

So for "Making something big" in week 8, I drew a sideboard in AutoCad and created the paths and pockets in the VCarve software. I have never tried AutoCad before, but have been quite pleased with AutoDesk's software. I have downloaded a free version for educators where I have a trial period.

The squares in the left side of the AutoCad files are a markup where a piece of the plywood was used and therefor missing. So in order to place my design correctly in relation to space, this square was included in the file. My idea about the sideboard is to paint it, but to let the ends of the plywood be visible to show the many layers.

3D Modeling

3D-moulding of a cloud in different programs.

This week I treid to worke with different kind of CAD-software as Neil Gerschenfed encouraged us to do. For ajusting my pictures I used Gimp, Paint and a iPhone app called PicFrame. I actually like the software Gimp for resizing and ajusting colors on my pictures. The app PicFrame has also some really nice filters for color and give the opportunity to make nice frames and putting together more photos ind the same frame.

I used Inkscape and CutStudio for my 2D-drawings but experienced some lack og features in CutStudio like options to share compleated files with other programs, and the opportunity to save my work in different formats. On the basis of this experience I chose to focus on Inkscape. In Inkscape I found a big variety in options of saving different file-formats and therefor a more easy way of the working between different programs. I ended up using Inkscape for most of my 2D-drawings for the lasercutter and the vinylcutter.

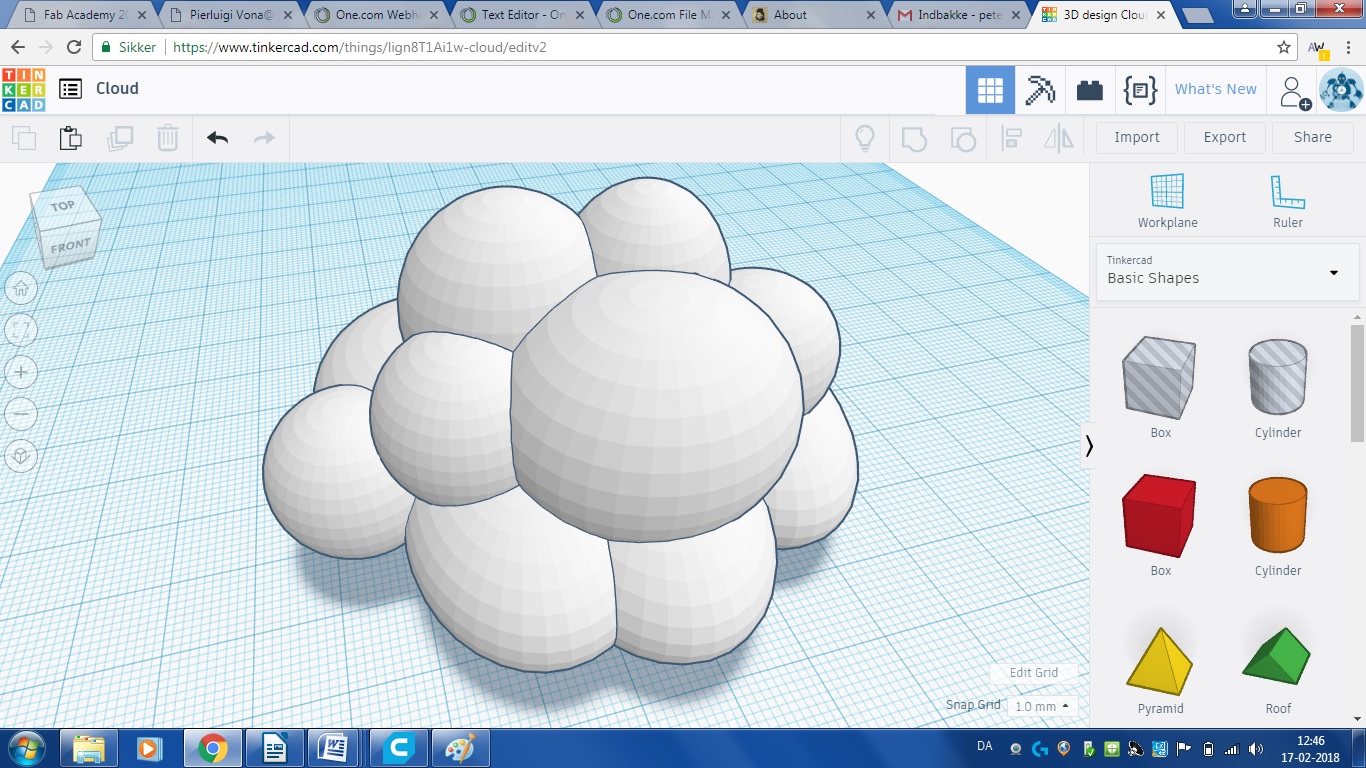

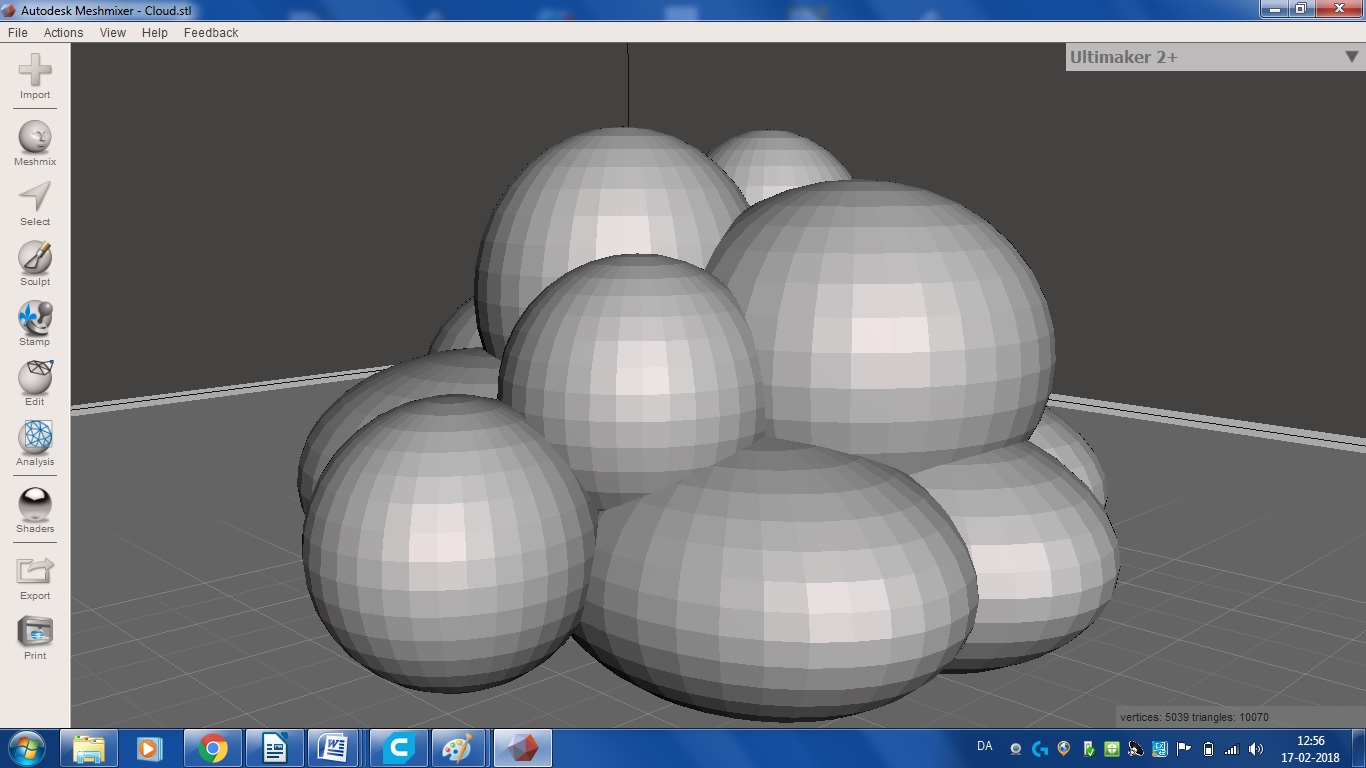

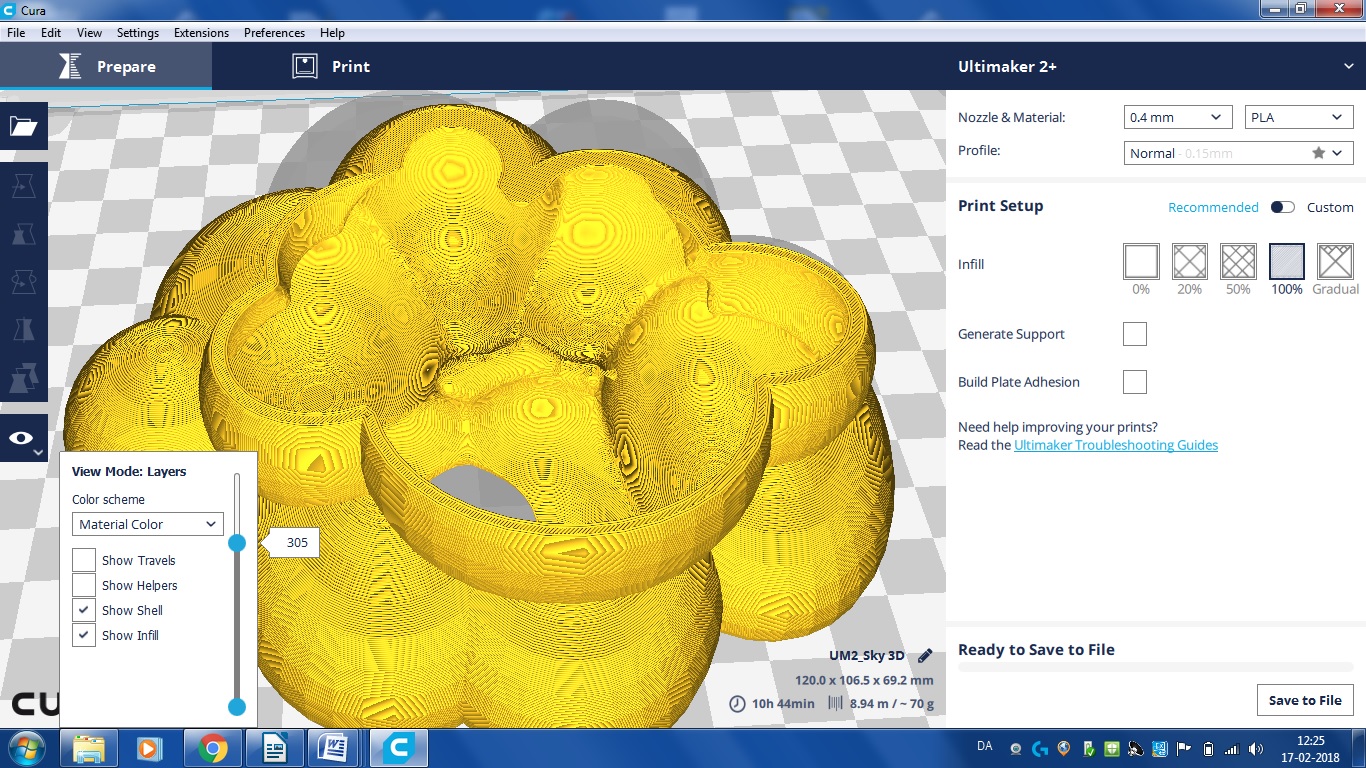

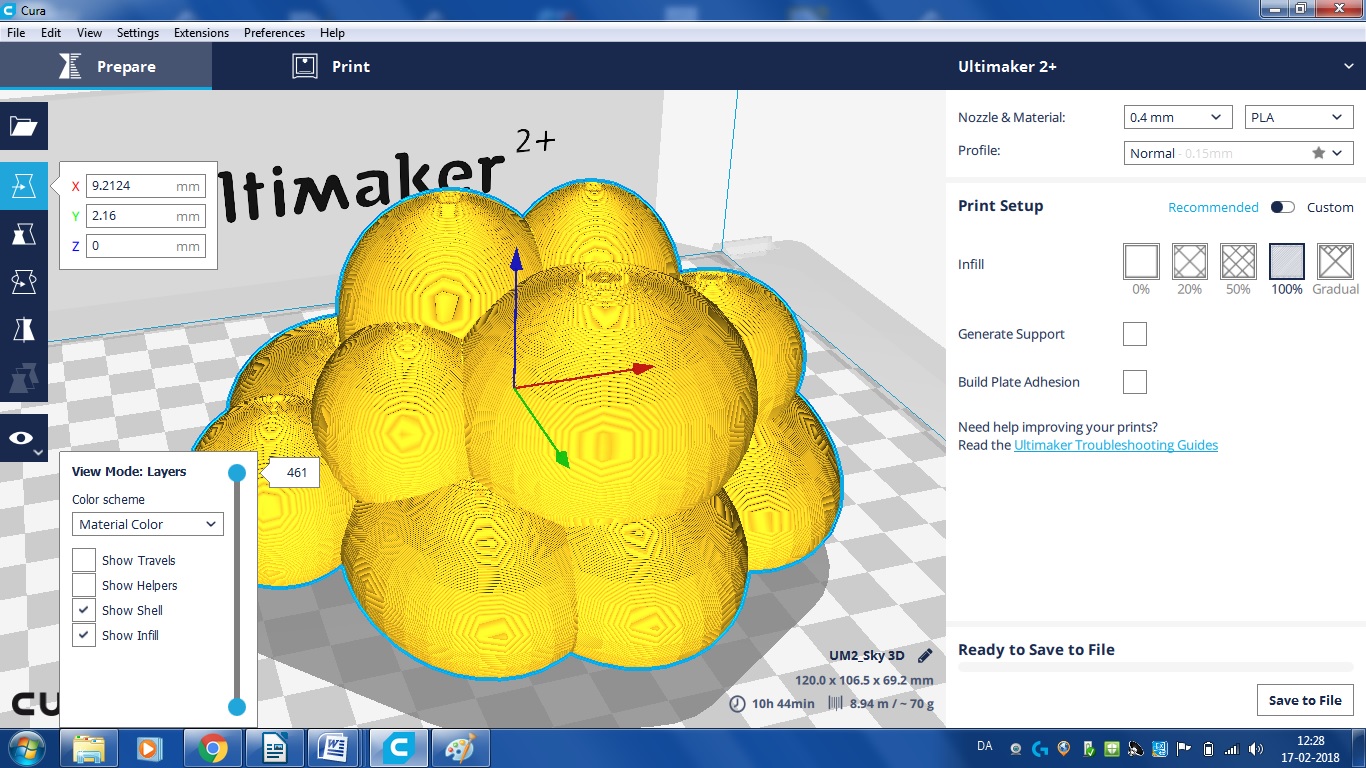

For my 3D-modelling I been around many different softwares and got a claer experience that there are many good softwares out there, but also that they are great for many different things. I been using Thinkercad, Fusion360, Meshmixer and PreForm to work on my cloudshape for the Final Project. At first I made a simple cloud in ThinkerCad by adding many circles or spheres together like the ballonpicture and thisway building up a cloudshape.